Over the last five years, the U.S. has been witness to world-changing events, economic hardships and political uncertainty.

As the resilient country we are, Americans have adapted both personally and professionally. Nothing may be as evident as in the way businesses have begun to pivot and shift manufacturing and procurement structures back to the states.

Overseas partnerships have long helped the bottom line of U.S. businesses, but companies are now factoring in the importance of getting products on time and at a more stable price.

Caplugs Manufacturing Facility in Erie, PA

The pandemic was the spark that started the current flame: shutdowns in the first two quarters of 2020 led to supply shortages and supply chain issues – partially caused by pandemic regulations and lack of reliable workers – and opened the eyes of many business owners. Cracks were beginning to show in the offshoring business model for the first time in many years.

As we moved out of the pandemic, lingering issues such as lack of raw materials and price instability continued to cause unrest. These issues have led companies to explore bringing manufacturing and purchasing back to the U.S., better known as reshoring or onshoring.

Nearshoring, or identifying alternative providers from neighboring or regional countries, has become an alternative manufacturing option for businesses over the last several years as well, but based on recent remarks from President Trump, it appears both nearshoring and offshoring will come with higher costs as we move forward in 2025.

Universal tariffs, and even higher tariffs for several countries, have put U.S. manufacturing in the spotlight once again. While higher costs due to these tariffs will play a large role in companies either expanding or completely switching to U.S. manufacturers and suppliers, there are several other “hidden” benefits to onshoring and reshoring.

As we are faced with one of the more volatile markets in recent memory, businesses are looking to protect themselves from rising costs and pricing fluctuations in any way they can. Onshoring eases each of these concerns by offering a more predictable pricing structure for materials and products.

American manufacturers aren’t expected to face the same tariff challenges as foreign manufacturers like those in Canada, China and Mexico. While certain raw materials used in U.S. manufacturing will see a price bump and cause some products to go up in cost, it will be nowhere near the price increases that come with 25% tariff spikes.

This will allow U.S. manufacturers to set prices at a more consistent rate than those who are being charged tariffs for each import. Furthermore, less volatile shipping costs are expected within the U.S. in 2025, creating even greater stability for domestically produced items.

This consistency and predictability not only saves on a company’s bottom line, but allows teams to better plan their budgets and allocate funds to different parts of their organizations.

Getting costs in line is only part of the battle. Businesses require their materials and products to be delivered on time, no matter what the political or economic climate may be.

Commodities produced in the U.S. don’t need to be shipped as far or across potentially dangerous oceans where harsh weather often arises. While it may seem obvious, it can’t be overstated; the closer to home your purchase, the quicker the items will get to you in most cases.

While shipping efficiency plays an important role in reducing lead times, fast turnarounds in production are just as key. With a domestic partner you can typically get samples in 24-48 hours, allowing you to approve projects and ramp up production quickly.

This can help U.S. businesses build rapport with their customers and expand operations at much quicker speeds.

Real-time problem solving with a sales team member

An American partner can also be beneficial for companies who prioritize agility in production. When a change in scale is required, domestic manufacturers can often handle these changes on the fly, shifting orders and delivery dates as needed, all while avoiding the long delays or high cost for expedited shipping from across the ocean.

Moreover, U.S. manufacturers often have traveling sales teams that can come directly to a facility to discuss new projects and any challenges like color and material changes, part changes and scalability requirements (from hundreds to millions). Depending on location, they can be to your facility the next day to put production into hyperdrive.

If an emergency situation arises, domestic manufacturers can often facilitate a request the same day, getting an important order completed in hours – not days or weeks.

Similar to issues with lead times, products traveling great distances can have bottlenecks in their supply chain. Onshoring and reshoring models simplify the supply chain and reduce the chances of experiencing shipping issues like lack of dockworkers, port congestion, waterway closures and extreme weather, to name a few.

Regionalized manufacturing makes it easier to “keep tabs” on shipments to see where certain deficiencies may be and allows for improvement with each shipment being made.

Another bonus of switching to U.S. manufacturing and procurement is improved communication. While we can now communicate with anyone around the world in real time from a smartphone, there are still unavoidable problems like language barriers and time zone differences.

Language barriers are not typically seen as a large sticking point, but they can sometimes have negative consequences with misunderstandings leading to errors in the design and production of a product. When time is off the essence, being able to communicate effectively is a major advantage.

Another problem is the need to consistently set up meetings in early morning or late-night hours to accommodate time zone differences, especially in the initial stages of a project.

Even further, foreign countries observe different holidays, meaning their facilities can be closed or key team members can be out of office when a critical part of design, production or shipping needs to be discussed.

Transitioning to a new manufacturer may seem like a huge lift. With the initial time and cost that needs to be put in, many teams may be hesitant to make the move. What typically isn’t considered is the fact that switching to new or updating custom tooling can pay off big in the long run.

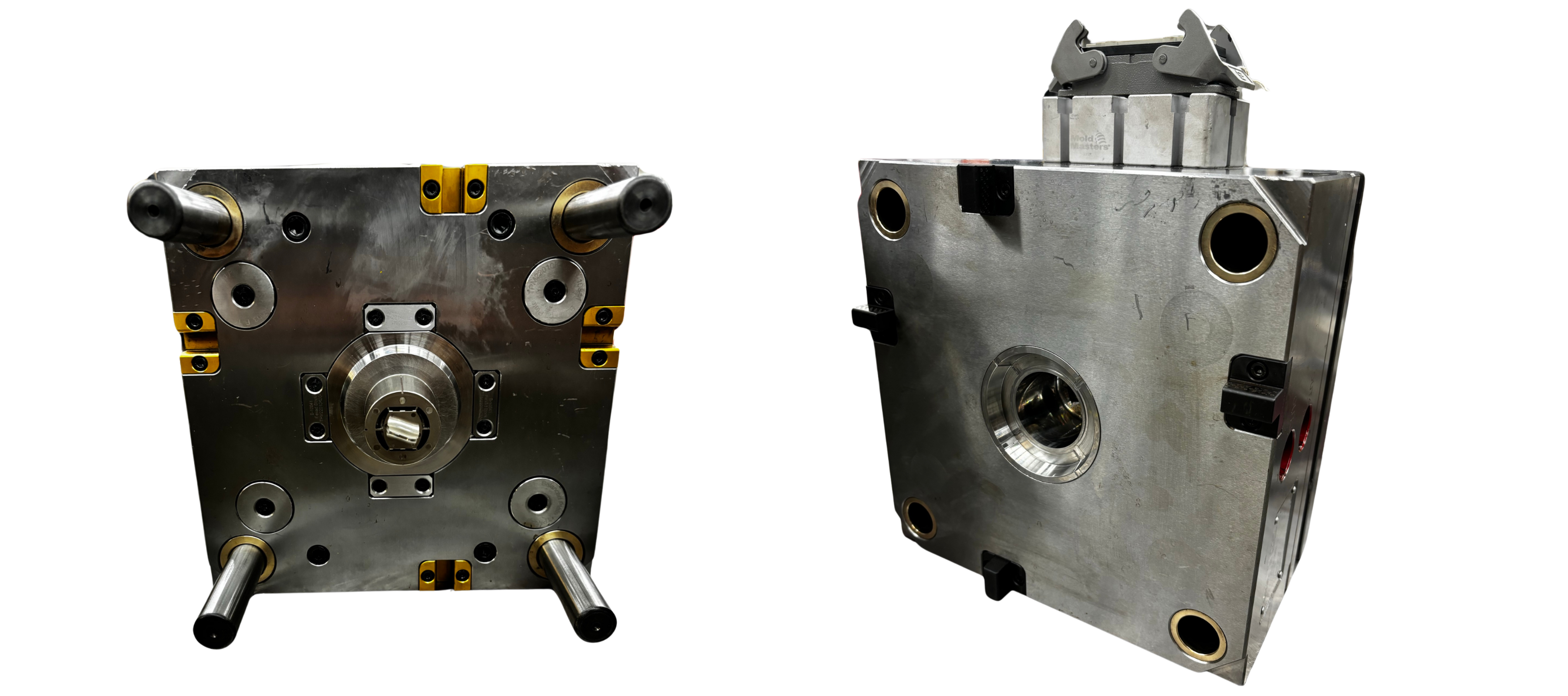

Custom Tooling

While there typically won’t be a noticeable difference in the quality of the materials themselves, updating tooling with a U.S. partner can allow for more efficient manufacturing. For example, more cavitations can be added to a newly remade custom tool if higher volume runs are now required for a part, which can greatly reduce lead times, accommodate an increased demand and even drive more business. Furthermore, onshoring can allow for updates to be made to a mold design when changes are desired or necessary.

If an offshore tool or custom stack has gone through many runs, it may be time to upgrade it anyway to improve overall product consistency. Choosing to onshore tooling and production also makes it easier to have immediate access to the manufacturer for any questions or changes to a design.

It’s no secret businesses are constantly looking for ways to de-risk and altogether avoid problems that can create quality, logistical and informational complications.

When manufacturing occurs domestically, teams can monitor manufacturing more closely, through regular communication and can address quality issues before they escalate.

When products are shipped, onshoring decreases the chances of shipping issues such as lost inventory, and if something were to happen to a shipped order, a replacement can typically be shipped faster than if it were coming from overseas.

Security is also a factor to consider, especially if you are allowing sensitive data or intellectual property to be sent electronically. While most operations you will work with internationally have security measures in place, partnering with a U.S. manufacturer helps ensure regulatory compliance is being followed and that critical data doesn’t end up in the wrong hands.

We can help your business on the road to onshoring. We understand the work that needs to be done to get manufacturing and procurement moved stateside and can make the process simple and easy.

From resourcing tasks like part and material matching to lending a hand with quantity and price point questions compared to a current supplier, we will take care of the hard stuff and let you worry about other areas of your business.

We will go through all the plastic parts you currently purchase and will get things “matched-up” for you by dimension, material and quantity. Long gone are the days of procurement teams handling these tasks. Our team will find exact matches and optional matches for your consideration – we may have options that perform even better for your application.

Free sampling of all catalog parts is also available before placing your first order. We’ll go the extra mile by creating a succinct plan for the quantities you will need, when you need them, along with any special packaging considerations. All of this is done with the constant support of your Caplugs product expert and service team.

Let us work with you to optimize your onshoring strategy for cost, quality and lead time. Give us a call at 1-888-CAPLUGS or send us an email to get started.