Whether you need a unique size, shape, material or color, or have specific requirements for your process, our full team of in-house engineers will work one-on-one with you through every step of the process. From initial design to final production, our goal is to create the product protection, masking or custom molding you require.

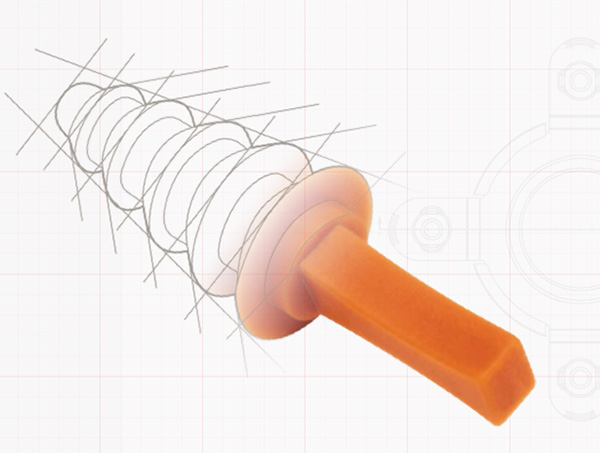

We utilize 3D modeling compatible with all CAD platforms. Our Design for Manufacturability analysis and practices ensure the most cost-effective and efficient solution to your specific application.

Prototypes are built in house to confirm fit requirements before production approval, ensuring high-quality outcomes. Single cavity prototype tools are used to prove our designs.

Tools made in house result in shorter lead times, easier modifications and lower costs — with new tools in as little as 4 weeks. We also offer a wide range of cavitation options and an extensive library of existing tools for scalability and efficiency.

Our wide range of manufacturing and equipment options allows us to efficiently produce the parts you need, whether a small volume run or millions of parts a year. Our formal verifications ensure part design and production processes comply with all your specifications.

From special packaging requirements, like corrugate free, to a range of shipment and inventory solutions, including JIT, EDI and Advanced Shipping Notice, we ensure your products arrive intact and on time, every time.

With our design expertise, in-house tool room and extensive molding capabilities, we can produce a custom part quickly and economically. Let the largest, most experienced engineering staff in product protection and masking develop exactly what you need.

Our team of experienced design engineers will help identify performance features from a wide range of available options to suit your application. Performance capabilities for product protection, masking and molded parts include the following:

Because every part and application have its own set of exact fit, temperature and quality requirements, Caplugs offers customized solutions ranging from fully custom part design to standard part modification and secondary finishing options.

Caplugs helps analyze your exact conforming needs and part requirements. This reduces production time and cost while ensuring repeatable quality for future molding and volume needs. Learn more about how design for manufacturability (DFM) can be applied to your products.